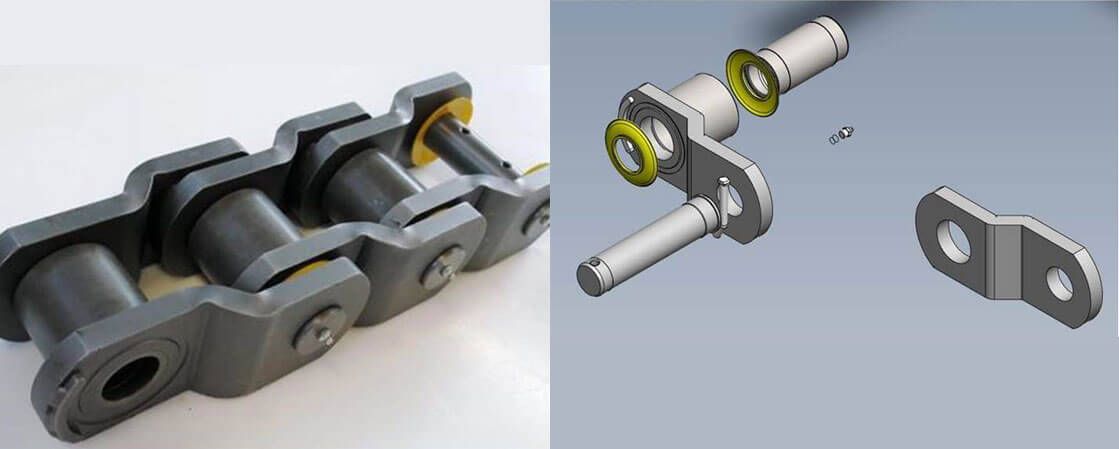

Low maintenance chains with sealings

The need to reduce or completely cancel the maintenance of the chains is addressed by ZMC with different solutions based on the working conditions and requirements of the specific sectors.In several cases the most effective way to reduce maintenance costs is to load the starting chain with an adequate amount of grease and to confine the lubricating product in the areas where it must perform its function. This objective is achieved by means of a system based on special sealings. In this way, the lubricating characteristics of the grease are exploited to the full, avoiding contamination by external agents and unnecessary dispersion towards other parts of the system.This solution has been successfully adopted in various applications. Here we present a case that belongs to the mining industry. This is a cranked link chain belonging to the category of so-called “Rotary chains” used to keep large drums in a rotary motion. Often chains of this type work in harsh conditions, at high speed and in the presence of highly abrasive agents.The solution developed by ZMC allows to keep the chain lubricated for long periods of time, making less frequent the relubrication intervals and sometimes eliminating completely the need to introduce new grease for the entire life of the chain.For more information, don’t hesitate to contact us