A CONFIRMATION OF QUALITY

Recognition of achievement is always a source of satisfaction, and it is with pleasure that we share our successes with our partners.ZMC recently gained ISO9001: 2015 accreditation after assessment of its management system. The inspection carried out by the prestigious Lloyds Register was successfully passed, confirming the validity of the “ZMC system”, without any observations or amendments to the existing procedures.Quoting from the final report issued at the end of the inspection:“The company shows a good propensity to improve its processes; the continuous search for refinement of the methods used is clear. ”“Overall, the impression is very good and it is recommended to continue with this approach.”In light of this accolade, ZMC looks to the future and is committed to driving success through keeping the goal of continual improvement at the center of all its endeavours.

This miniature bicycle symbolises the ZMC culture regarding experience, technical knowledge, accuracy and quality. Those who partner with ZMC meet a company that will understand and satisfy every need without forgetting the important aspect of the human relationship.

This miniature bicycle symbolises the ZMC culture regarding experience, technical knowledge, accuracy and quality. Those who partner with ZMC meet a company that will understand and satisfy every need without forgetting the important aspect of the human relationship.

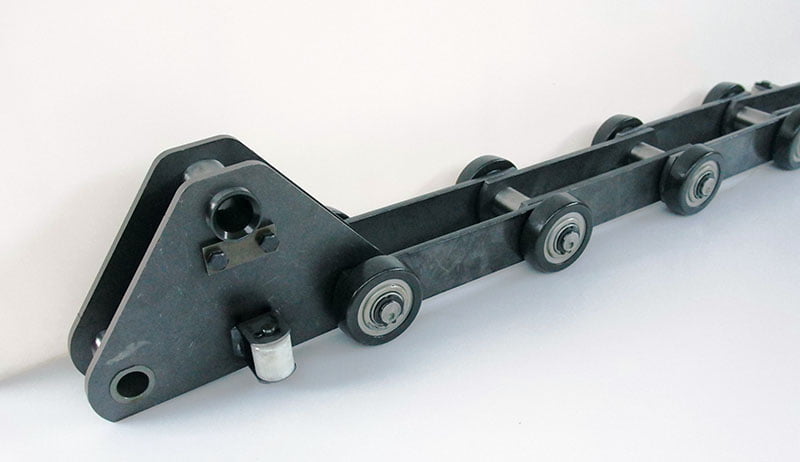

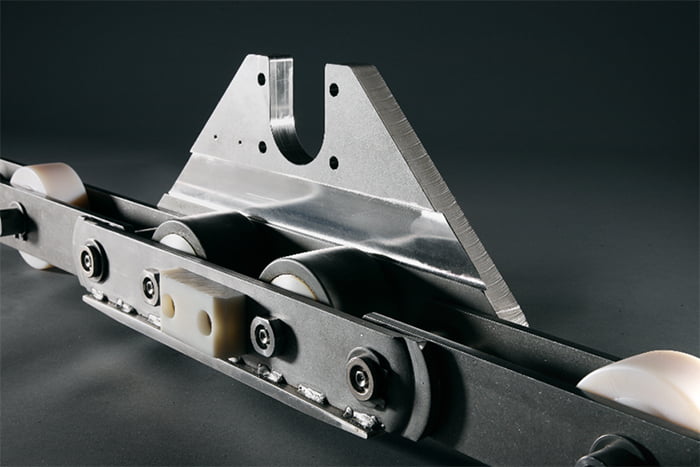

The application of protective layers that precede the final painting of the cars, vans and trucks, takes place in pre-treatment plants, through which the chains follow the path of a sine wave. Two parallel chains slide on side guides which support steel carriers and in turn carry the car body.The process of applying corrosion inhibiting layers is achieved by conveying the car body through chemical baths. The nature of the conveyor path, having many rises and falls, is called the Pendulum system, and the chains take the same name.More recent systems allow the car body to also be rotated inside the chemical bath for more effective surface coating, this type of system is called Ro-Dip.

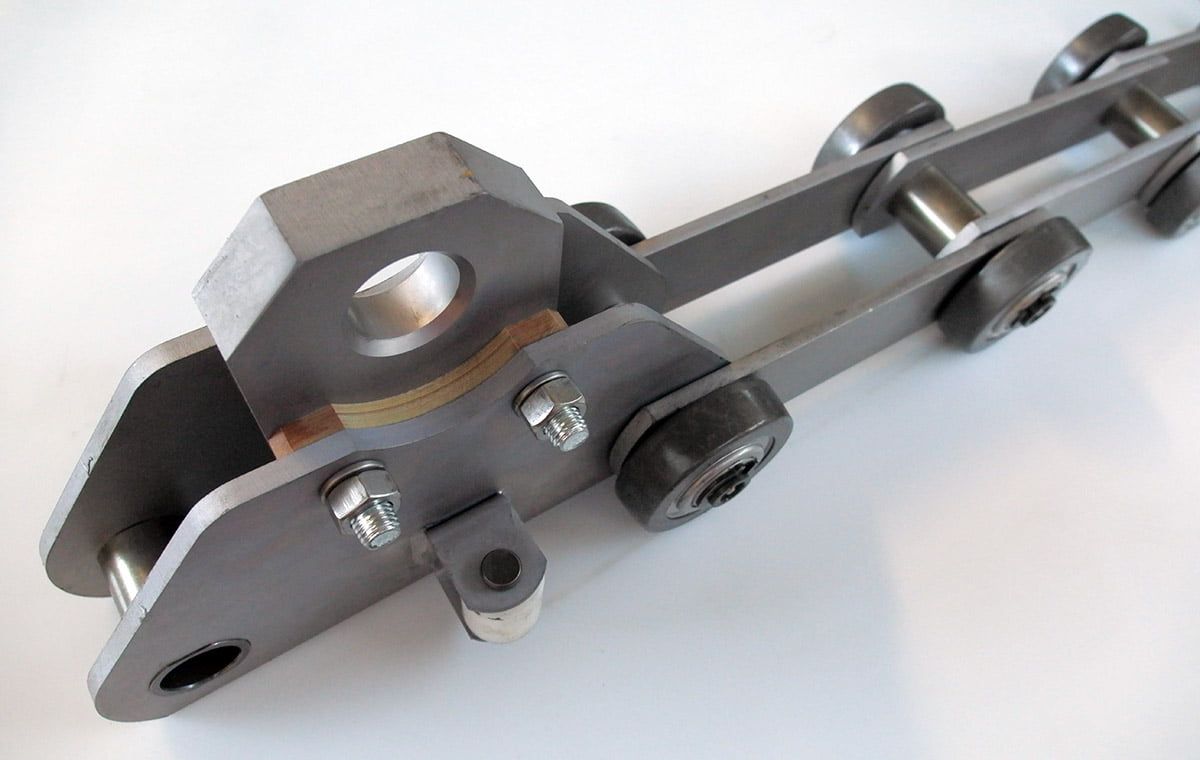

The application of protective layers that precede the final painting of the cars, vans and trucks, takes place in pre-treatment plants, through which the chains follow the path of a sine wave. Two parallel chains slide on side guides which support steel carriers and in turn carry the car body.The process of applying corrosion inhibiting layers is achieved by conveying the car body through chemical baths. The nature of the conveyor path, having many rises and falls, is called the Pendulum system, and the chains take the same name.More recent systems allow the car body to also be rotated inside the chemical bath for more effective surface coating, this type of system is called Ro-Dip. There are significant technical challenges to be considered in providing chains that operate in these applications. The chains are highly stressed from a mechanical and corrosion resistance point of view. Innovative features include the choice of materials suitable for the operating environment, (in some cases Duplex stainless steel) the design and construction of sturdy bearing wheels, and an internal lubrication facility to operate with automatic lubrication systems.

There are significant technical challenges to be considered in providing chains that operate in these applications. The chains are highly stressed from a mechanical and corrosion resistance point of view. Innovative features include the choice of materials suitable for the operating environment, (in some cases Duplex stainless steel) the design and construction of sturdy bearing wheels, and an internal lubrication facility to operate with automatic lubrication systems.