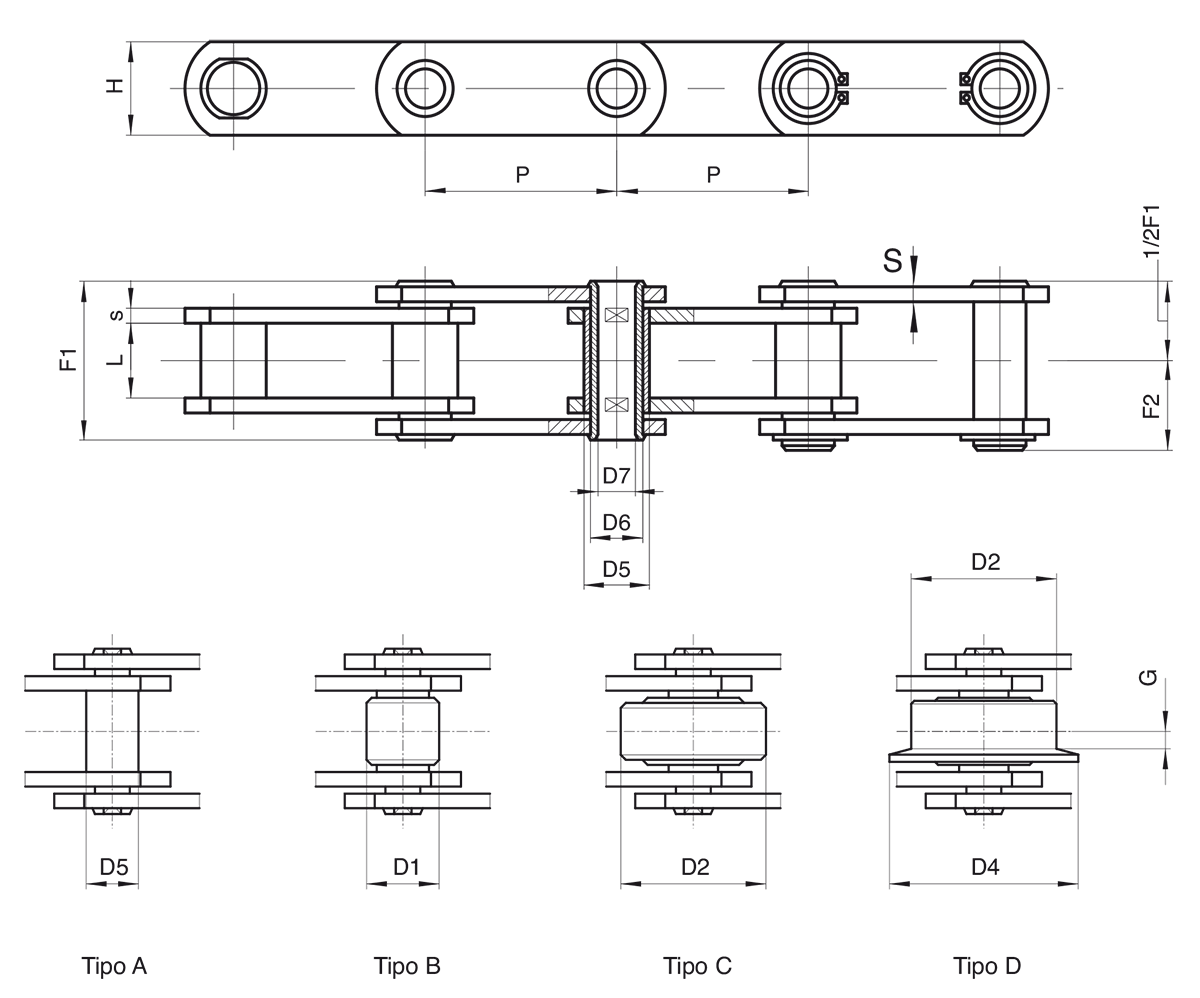

Chains according to ISO 1977 DIN 8167 with Hollow Pin

| wdt_ID | Chain N. | P mm | L mm | D1 mm | D2 mm | D3 mm | D4 mm | G mm | D5 mm | D6 mm | D7 mm | H mm | S mm | F1 mm | F2 mm | Breaking load N | Breaking load N* | Weight per attach. kg/m ** |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | MC28 | 50 | 20 | 25 | 36 | 45 | 45 | 4,50 | 17 | 13,00 | 8,20 | 25 | 3 | 36,00 | 20,50 | 28.000 | 40.000 | 4,30 |

| 2 | MC28 | 63 | 20 | 25 | 36 | 45 | 45 | 4,50 | 17 | 13,00 | 8,20 | 25 | 3 | 36,00 | 20,50 | 28.000 | 40.000 | 3,80 |

| 3 | MC28 | 80 | 20 | 25 | 36 | 45 | 45 | 4,50 | 17 | 13,00 | 8,20 | 25 | 3 | 36,00 | 20,50 | 28.000 | 40.000 | 3,20 |

| 4 | MC28 | 100 | 20 | 25 | 36 | 45 | 45 | 4,50 | 17 | 13,00 | 8,20 | 25 | 3 | 36,00 | 20,50 | 28.000 | 40.000 | 2,80 |

| 5 | MC28 | 125 | 20 | 25 | 36 | 45 | 45 | 4,50 | 17 | 13,00 | 8,20 | 25 | 3 | 36,00 | 20,50 | 28.000 | 40.000 | 2,50 |

| 6 | MC56 | 63 | 24 | 30 | 50 | 60 | 60 | 7,00 | 21 | 15,50 | 10,20 | 35 | 4 | 45,00 | 25,00 | 56.000 | 90.000 | 9,10 |

| 7 | MC56 | 80 | 24 | 30 | 50 | 60 | 60 | 7,00 | 21 | 15,50 | 10,20 | 35 | 4 | 45,00 | 25,00 | 56.000 | 90.000 | 7,90 |

| 8 | MC56 | 100 | 24 | 30 | 50 | 60 | 60 | 7,00 | 21 | 15,50 | 10,20 | 35 | 4 | 45,00 | 25,00 | 56.000 | 90.000 | 6,20 |

| 9 | MC56 | 125 | 24 | 30 | 50 | 60 | 60 | 7,00 | 21 | 15,50 | 10,20 | 35 | 4 | 45,00 | 25,00 | 56.000 | 90.000 | 5,40 |

| 10 | MC56 | 160 | 24 | 30 | 50 | 60 | 60 | 7,00 | 21 | 15,50 | 10,20 | 35 | 4 | 45,00 | 25,00 | 56.000 | 90.000 | 4,70 |

(*) Breaking load with heat treated plates

(**) Weight for chain with roller “Type C”

Additional features:

– rollers of nylon, delrin, etc.

– in STAINLESS steel

– surface treatments of zinc plating, nickel plating, etc.

– pre-tensioned and labelled